What You Need to Know About Replacing Caster Wheels

Ordering new caster wheels can be overwhelming because of the seemingly infinite combinations of features and options. We’ve created this guide to simplify the process for you so you can keep your wheels moving smoothly. While it isn’t entirely exhaustive of all possible options, it contains the most crucial components to decide on when choosing the right caster wheel replacement.

BONUS: Download our FREE caster wheel buying guide at the end of this article!

When to replace caster wheels:

You might be wondering, when should I replace my caster wheels? The most obvious answer is that they should be replaced when there is notable damage to the caster or wheels. However, caster wheels should also be replaced when there is any corrosion around the housing or hardware, the wheels are worn out or cracked, or do not lock or roll smoothly anymore.

What you need to know about replacing caster wheels:

The easiest way to buy a replacement caster wheel is by sharing the make and model of your machine or cart with Triad Service Center so that we can determine the correct part number.

If you don’t know this information or would like to switch to a different type of caster wheel, you’ll need to take some measurements and determine the following:

-

Diameter and width of the wheel

-

Mounting height (if the machine or cart needs to be a specific height)

-

-

Top plate measurements

-

Caster stem type

-

Optional caster brake

-

Required load capacity for each caster

This may seem like a lot of work, but it’s simpler than it seems, and this guide will walk you through it.

-

Measuring the diameter and width of the wheel

When looking to replace a caster wheel, you should start by measuring the wheel’s diameter and width/thickness. If your cart or machine needs to be a certain height, then you’ll also need to measure the mounting height (bottom of the wheel to the top of the plate where the caster wheel attaches).

-

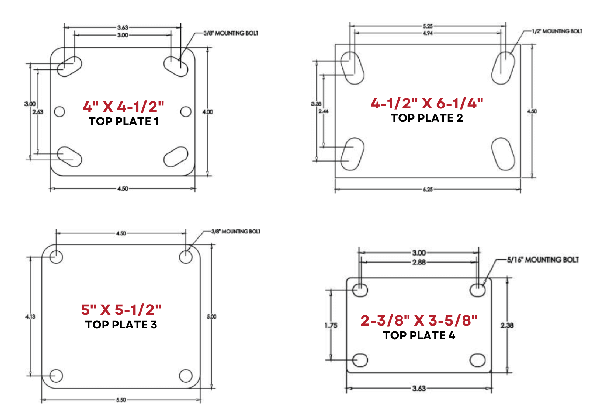

Measuring the top plate

Next, you’ll need to measure the top plate. There are 4 different standard top plates as pictured below. If the top plate of your caster wheel does not match any of these standard plates, please measure yours to the best of your ability and provide us with the measurements.

-

Top Plate 1: 4” x 4-1/2”

-

Top Plate 2: 4-1/2” x 6-1/4”

-

Top Plate 3: 5” x 5-1/2”

-

Top Plate 4: 2-3/8” x 3-5/8”

-

Determining the stem type

Aside from plate size, caster wheels also have varying stems. Stems are the piece of the caster wheel that attaches the wheel and base to the top plate. You’ll need to determine the correct stem type for the caster you need to replace. While there are many types of stem attachments, here are the four most common standard caster wheel stems:

The threaded stem caster is the most common type of stem caster. As its namesake implies, it has a threaded stem with a specific thread count, length and width (⅜”-¾”).

Grip-ring stem casters have a stem with a small friction ring to hold the stem in the round insertion hole. These are commonly found on mop buckets and office chairs but can be found elsewhere.

Another common stem caster is an expanding stem caster, in which the stem adapter expands to fit into a variety of inner diameter round or square legs or tubes. Of course, this varies by adapter kit and tube size, so take note of the exact size and shape of the stem necessary.

Alternatively, a hollow kingpin caster does not have a stem but instead has an opening for a bolt to be inserted in place of an attached stem. These casters are a great choice if you can’t find a caster with the correct size threaded stem.

-

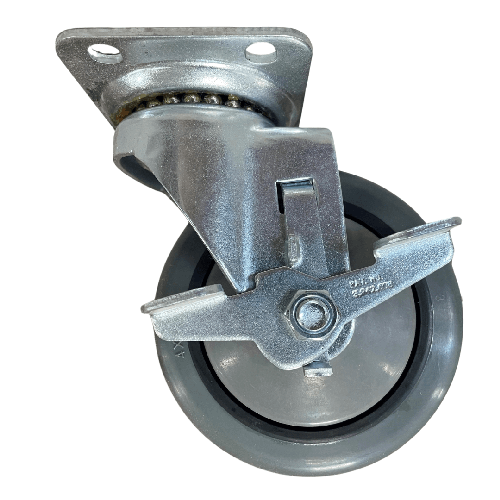

Deciding on an optional caster lock/brake

For floor cleaning machines and other commercial units, you likely won’t need an additional lock or brake on the caster itself. However, for units like grease caddies and manual carts, a lock/brake can be a handy addition to prevent unwanted movement and ensure safe use.

There are several kinds of caster locks, but for the sake of brevity, we won’t bore you with all the details. The most common caster wheel brake is a side lock which stops the rotation of the wheel with a pedal on the side of the wheel.

If you will need a caster with a lock/brake on the wheel, please specify this when ordering.

-

Determining the required load capacity

To determine the required load capacity for your caster wheels, follow these instructions and refer to the safety factor conditions below:

-

Add the maximum load weight for your cart to the weight of the cart.

-

Divide this number by the number of casters to be used.

-

Determine what safety factor* applies to your intended use conditions and multiply this number by the total you determined in step 2.

-

The resulting number is the required load.

Safety factor is dependent on intended use conditions:

Indoor use:

Manual Transport = 1.35 (under 3 mph)

Power Driven Transport = 2 (under 3 mph)

Outdoor use:

Manual Transport = 1.8 (under 3 mph)

Power Driven Transport = 3 (under 3 mph)

Again, the easiest way to replace a caster wheel is to provide us with the make and model of your machine or cart so that we can determine the correct replacement part. However, if you’re looking to switch to another type of caster wheel or do not know the make and model of the information, please follow the above instructions and share the specifications with us so we can get you the right part.

Download our FREE caster wheel buying guide for quick reference:

Questions?

As always, if you need any assistance with determining what kind of caster wheels to order for your machine, cart, or caddy, please don’t hesitate to contact us:

Call us at (888) 834-9948

Email us at parts@triadservice.com

Or submit a help request here: Parts Request

©